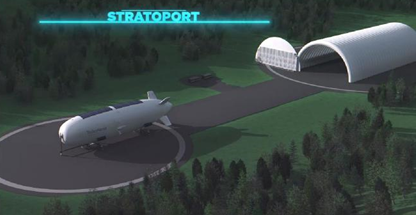

Stratobus™ project, developed by Thales Alenia Space France, is an autonomous stratospheric system, High Altitude Platform System, HAPS, including the vehicle itself, its payload and the ground infrastructure.

Powered by Solar Energy, it can withstand its steady state position in stratosphere up to 1 year, autonomously, providing a geostationary platform for multi-mission purposes.

Stratobus™ Features

Stratobus is a 140 m length and 32 m diameter airship positioned at an altitude between 18 to 20 km in the lower layer of the stratosphere, where the winds are moderates and the air density is still sufficient to allow buoyancy.

The Stratobus platform consists of a flexible envelope maintained in shape by helium in overpressure. Its total weight is around 9,000 kg including a payload of over 250 kg. These characteristics mean that it can reach altitudes around 20 km and thus enjoy a visibility horizon of 500 km.

The platform and its on-board solar energy allow it to counter winds of the order of 25 m/s and thus remain stationary over a point or area of interest with high availability.

Stratobus™ missions

Stationed at the edge of the stratosphere, about 20 km above sea level, just above air traffic, but much closer to the earth than a satellite, Stratobus is able to provide regional coverage at a very high level high resolution. The airship can perform many missions, from precision surveillance of a given area or control of our environment, to telecommunications and navigation operations. It is intended for many applications such as border surveillance, oil operations and maritime piracy surveillance, vessel identification, air quality measurement, GSM network reinforcement during exceptional events or improved GPS system in heavy traffic areas. As part of commercial telecommunications missions, Stratobus is complementary to the global telecommunications ecosystem by offering fixed and mobile connectivity solutions complementary to those provided by terrestrial or satellite networks.

Several customers are showing interests in these applications not only because of StratobusTM’s incomparable performances, but also because of its low operational cost and minimal ecological footprint.

Stratobus™ key technologies

Such a system is dreamed since decades because of a position never reached permanently. Some industrials endeavoured to develop permanent stratospheric high capacity airship but they all faced technologies or operations issues.

The StratobusTM airship benefits incorporates many technological innovations. The keys are mass and energy managements. With its 1000 m² solar generator and its high energy density batteries, StratobusTM allows a maximization of sun energy while minimizing the mass and surface area of the envelope.

In order to capture a maximum of solar flux, the balloon is able to rotate around its main axis allowing it to position its solar generator facing the sun at any time of the day and in any season.

Another key element is the envelope itself as to manage the structure of the airship, the sealing and this with a very low surfacic mass.

Stratobus™ timescales

A structuring co-engineering phase for the project started in 2016 at the Cannes site with Thales Alenia Space and its partners.

The development was split into two phases. A first phase devoted to the preliminary study of the platform and technological demonstrations. A second phase related to the development of the system solution, including the platform, its ground segment and the missions.

During phase 1, the analyses and the preliminary design were correlated with numerous mock-ups. More than 3,000 demonstrations have been carried out, from the basic component to the small scale demonstrator. All the technologies have been tested and for many in a representative environment. Phase 1 was closed in 2020 and the consortium concluded that the StratobusTM concept was feasible with the technologies mastered.

Phase 2 was initiated in 2019 with, initially, a study phase of missions and operational concepts.

An operational demonstration stage is planned for 2024 to 2025 on the basis of small-scale models called MVP for Minimum Viable Product. As soon as the stratospheric demonstration on reduced scale is completed, the first full scale operational model will be built and tested. The overall schedule depends on the financial scheme that is a permanent challenge for such a monumental development.